What’s the Difference between Process Excellence (PEX), Operational Excellence (OpEX), and Business Excellence (BEX)?

(Updated November 16, 2023) Although the terms Process, Operational, and Business Excellence are not the same, they are frequently misused and/or confused with one another. We venture to guess that if you asked 100 people about the difference between each of these terms, you’d likely get 101 different answers.

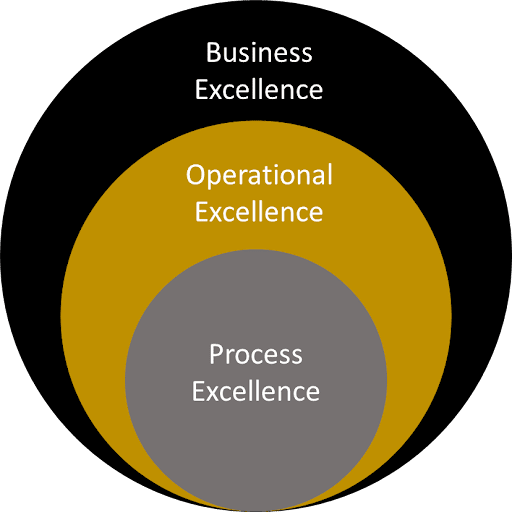

From a “textbook” perspective Process, Operational, and Business Excellence form a hierarchy. Process Excellence is a subset of Operational Excellence and Operational Excellence is a subset of Business Excellence.

.

Business Excellence includes:

- Operational Excellence

- Process Excellence

Operational Excellence includes:

- Process Excellence (and all of the paradigms, methods, and tools required for process work)

Process Excellence includes:

- Standardization of Tasks

- Optimization of Workflows

- Management of Work at Scale

- Responsive Exception Handling

In any organization, achieving optimal business performance is highly dependent on how effectively a team manages its efforts for achieving excellence. It’s also dependent on how well all the sub-components involved in PEX, OpEx, and overall Business Excellence are deployed. The most successful companies understand that effectively systemizing every aspect of their business allows for continuous improvement and deployment of best practices.

Achieving “excellence” is therefore about understanding how work is getting done from tasks to workflows to processes which ultimately roll into an organization’s overall business systems. An organization also needs to provide the necessary resources and systems to realistically achieve optimal outcomes. A well-orchestrated effort across all areas is what creates the value that an entity can deliver. Once systematized and aligned, a company can focus on managing exceptions rather than trying to keep the core of its work moving in any one direction.

Process Excellence (PEX)

Process Excellence is concerned with making processes more efficient and effective through design and testing. The main goal is to deliver consistent, positive outcomes with minimal variation (which Six Sigma tackles) and waste (which Lean deals with). Process Excellence teams are responsible for ensuring that processes within their organization run smoothly and consistently achieve pre-defined results.

The team is commonly comprised of individuals from across the company to develop new ways of working, implement improvements, and ensure that everything is running smoothly. The most effective means of building and managing processes is to look horizontally across an organization rather than working solely within traditional vertical reporting silos.

As part of process excellence, organizations look to Six Sigma which uses statistics and data analysis to reduce errors and defects. By incorporating this approach, companies can improve cycle times while reducing production defects. The core idea of yet another process improvement approach, Lean, is quite simple: relentlessly work on eliminating the “Seven Deadly Wastes” from processes:

- Overproduction

- Waiting

- Transport

- Excess/Unnecessary Motion

- Over-processing

- Inventory

- Defects

In general, it’s not critical for organizations to use Six Sigma, Lean, or Lean Six Sigma to achieve business improvement. And for many non-manufacturing environments, Six Sigma or Lean won’t even apply. However, the fundamental idea is that achieving process excellence will require in-depth analysis and frameworks that can help an organization improve. Most enterprise organizations don’t have the resources to design process improvement across the company all at once.

At HighGear, we use the idea of “emergence” to emphasize the point that iterative improvement is superior to an “all-or-nothing” approach. Getting started is better than getting “hamstrung” by trying to map a complex multi-departmental process across the entire organization.

A primary goal of PEX is to create smooth workflows; ideally, ones that are free of bottlenecks, inventory gaps, and delays which in turn roll into larger processes that affect the value chain and ultimately hinder competitive advantage. Examples of strategies to improve workflow include:

- Reduced Changeover Times. This makes it faster to switch between the production of different products or services.

- Avoidance of Batch Operations. Batching is the opposite of flow and inherently creates bottlenecks, waiting, and inventory.

- Organizing Equipment or Routing of Work. The goal here is to reduce motion, transport, waiting, and defects or human error.

Process and Operational Excellence are frequently used interchangeably, but doing so is not wholly accurate. According to the Process Excellence Network, the keys to Process Excellence are noted below.

Put your customer at the heart of it.

- Know what you’re doing.

- Change what you’re doing.

- Lead your people.

- Get someone (or something) else to do it. Note: For some organizations, this is the only part of process improvement they’ve embraced and HighGear doesn’t approve of this philosophy.

- Keep on top of the tech.

- Be prepared to fail.

However, PEX should be understood as being a subsection of Operational Excellence. More simply put, OpEX is a summation of how an organization’s processes work or don’t and why. And it should be noted that these outcomes are driven not only by the processes themselves but by the people and systems that envelope process execution.

Operational Excellence (OpEX)

Operational Excellence is a broader concept than Process Excellence. PEX is concerned with processes, but operational and transactional environments have more going on within them than merely the activities that guide them. OpEX is an attitude that embraces certain principles and tools to create a culture of perpetual improvement. Operational excellence means every employee has “buy-in,” meaning they can see and improve upon the flow of value to their customers. It is particularly concerned with corporate culture and how the organization is viewed from a value creation perspective.

This approach employs the lower-level tools of previously mentioned continuous improvement methodologies, such as Lean and Six Sigma. Operational Excellence is about how people, technology, tools, and other resources combine and interact with each other and with your processes to form key components of value delivered.

OpEX defines an organization’s direction, identifies and mitigates the risks to getting there, manages change, and drives continuous improvement. Having an integrated management system reduces overlap, redundancy, and conflict. It also encourages a culture of operational discipline, which is commonly described as doing the right thing, the right way, every time; i.e., “Do it right the first time.” See, your grandfather was right. Principles such as integrity, a questioning attitude, level of knowledge, checks/balances, and formality are expected of each and every employee.

[Note: OPEX is an accounting term for Operational Expense, whereas OpEX denotes Operational Excellence]

Business Excellence

Moving to a more macro view, Business Excellence encompasses both PEX and OpEX with the perspective of achieving results. Besides overall business strategy, it includes investor, customer, partner, and stakeholder communication. It helps an organization look beyond its proverbial walls and guides the overall development of the organization into the future.

Efficient processes by themselves are no guarantee of success. Like a perfectly tuned car being driven off a cliff. Your PEX may guide the most efficient widget manufacturing, but if no one is buying widgets anymore, what good is that efficiency? And if your “widget-1” manufacturing line duplicates the efforts of your “widget-2” manufacturing line, then OpEX is missing.

However, efficient processes and well-coordinated resource sharing will not save a weak or wrong business strategy. Business Excellence requires a holistic outlook of the entire organization in the context of the larger business environment. It requires your organization to see that widget-1 usage is dead, widget-2 usage is decreasing, and that your Product Development Department ought to be diving into how to best make widget-3.

Summary

- Process Excellence (PEX) – creating effective, efficient processes delivering consistent output with minimal variation and waste.

- Operational Excellence (OPEX) – PEX plus culture, people, resources, systems, and how they can optimally work together.

- Business Excellence – focused upon delivering overall results in a pragmatic, consistently successful fashion, now and in the future.

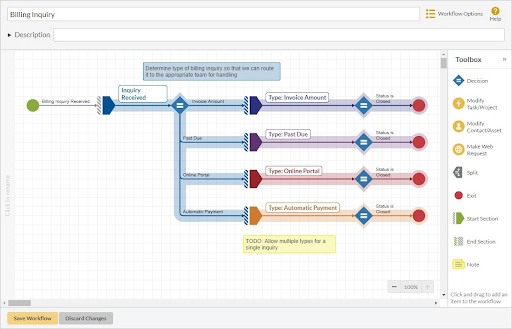

Just as in most things in life there are no shortcuts to achieving excellence across the board. However, so much technology has emerged in the era of digital transformation over the last several years, that it is possible to do more with less. For example, HighGear’s No-Code Workflow Software Platform is designed to help your company achieve Process and Operational Excellence. It channels the flow of all your projects. With a solid workflow tool, you can efficiently guide the flood of project tasks that need to happen along the way, with project outcomes becoming fully formed as they flow through different processes, checks, and balances. It eliminates the need for assigning tasks, managing work, and tracking progress and returns managers back to leading.

In the continual drive towards Business Excellence, HighGear’s workflow software platform will enable new product development by allowing everyone to see exactly what the status of any task or assignment is, keeping work from falling through the cracks, and ensuring visibility into the tasks. HighGear is a “turn-key” system that does not require any programming or coding, allowing your IT department to continue its important work. More importantly, your business analysts will be able to strive for Business Excellence through an intuitive, drag-and-drop platform, without hiring programmers, developing homegrown IT solutions, or adapting to low-code software.

Please feel free to Schedule a Demo to learn how we can help you to continue achieving Business Excellence!