Josh Yeager gives his thoughts on using Lean BPM to manage Product Lifecycle Management processes. PLM is close to Josh’s heart: as HighGear’s Chief Operating Officer, he has led and built the HighGear Product Development team, using HighGear’s Lean BPM capabilities to manage its own development.

Product lifecycle management (PLM) is the process that manages the inception, planning, design, construction, marketing, delivery, and customer service for a product. Each of these elements is its own discipline, so PLM is responsible for keeping the big picture in view and coordinating the overall process.

What Lean BPM Brings to PLM

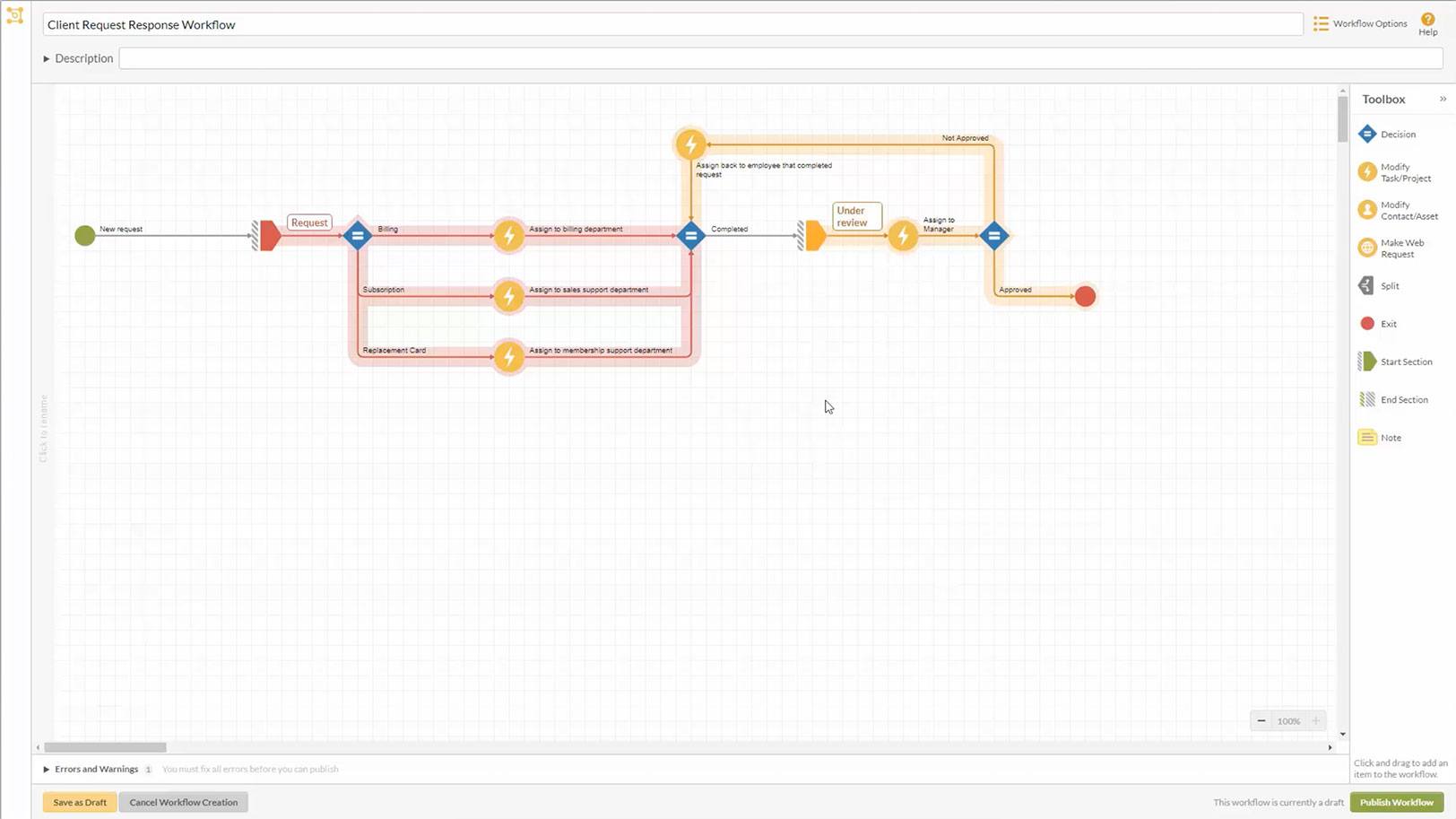

Lean BPM (Business Process Management) is an excellent tool for all stages of the PLM process.

1. Inception

During idea inception, Lean BPM tools like HighGear help gather ideas and coordinate their development. A good process at this stage ensures that ideas from brainstorming are retained and refined. It also gathers ideas over time and helps the team contemplate and refine them.

2. Planning and Design

In planning and design, good processes control the chaos of the creative process without slowing it down. They help management see progress and understand risks and timelines, and they also help the teams coordinate effectively, even when spread across many locations or time zones.

3. Construction and Delivery

Lean BPM demonstrates its biggest strengths during construction and delivery. All the processes and data that must be tracked fit smoothly into the overall processes. Additionally, Lean BPM’s focus on continuous improvement makes it easy to streamline those processes and make them more efficient, not only for the existing iteration but for those that follow.

4. Marketing

Marketing can also benefit from Lean BPM: tracking product road maps is always difficult, however an effective set of processes makes communicating changes from the design, through to construction teams and on to the marketing people that much easier. A BPM system also helps marketing track the many small tasks and projects that they must do to communicate the product’s benefits to the sales channel, prospects and customers.

5. Customer Service

When the customer service team takes responsibility for a product, a Lean BPM system gives them easy access to the product’s complete history. A Lean BPM platform provides a unified work platform, document and data repository, so the product’s entire history can be accessed If needed, and only by those with the authority to access that information. It also smooths their communication and ensures that customer needs don’t slip through the cracks, and will also integrate with CRM systems.

Summary

All of these groups benefit from automated processes and continuous improvement enabled by a Lean BPM system. There is an even more valuable benefit: feedback between groups. As design and construction encounter problems, the system can rapidly connect them to the planning team to find solutions. When marketing and customer service hear new ideas from customers, the system can help them pass those ideas back to the other groups. And every group can add ideas to the list for the next round of inception.

These processes can be complex and often difficult to implement. This is why Lean BPM also emphasizes continuous improvement and emergent process discovery. By implementing basic processes first and then working with each team to improve them over time, starting is easy and the final result is excellent.

Ease of use, smooth collaboration, efficient processes, and continuous improvement are the hallmarks of Lean BPM, and particularly HighGear.