What does it mean to achieve excellence in business? Operational excellence focuses on continuously improving processes to deliver the highest levels of service and quality. This concept also shows the value of refining your business operations so that you have a more sustainable competitive advantage.

Of course, achieving operational excellence is no simple task. While the goal is clear, the journey to improvement can be highly complex—especially at the enterprise level. But, with the right approach, any organization can easily unlock its full potential.

That said, let’s dive deeper into the concept of operational excellence, its core principles, and how to achieve it.

What Is Operational Excellence?

Operational excellence is a concept with several different interpretations. It can be broadly defined as executing a business strategy more effectively and consistently than your competitors. In turn, this should result in increased revenue, lower operational risk, and reduced costs.

For some business owners, operational excellence is considered an organization-wide effort where all employees have the same goal. If you follow this definition, then excellence is usually achieved when your teams work together to create a continuous flow of value for your customers.

On the other hand, many organizations define operational excellence as a philosophy. This approach embraces problem-solving, teamwork, and strong leadership as the keys to continuous improvement.

So, is operational excellence a set of activities or a mindset? At HighGear, we strongly believe that it’s both.

The role of operational excellence is to align your culture, processes, and strategies to create lasting improvements in your business’s performance.

Remember: There’s a difference between process, business, and operational excellence!

10 Core Principles Of Operational Excellence

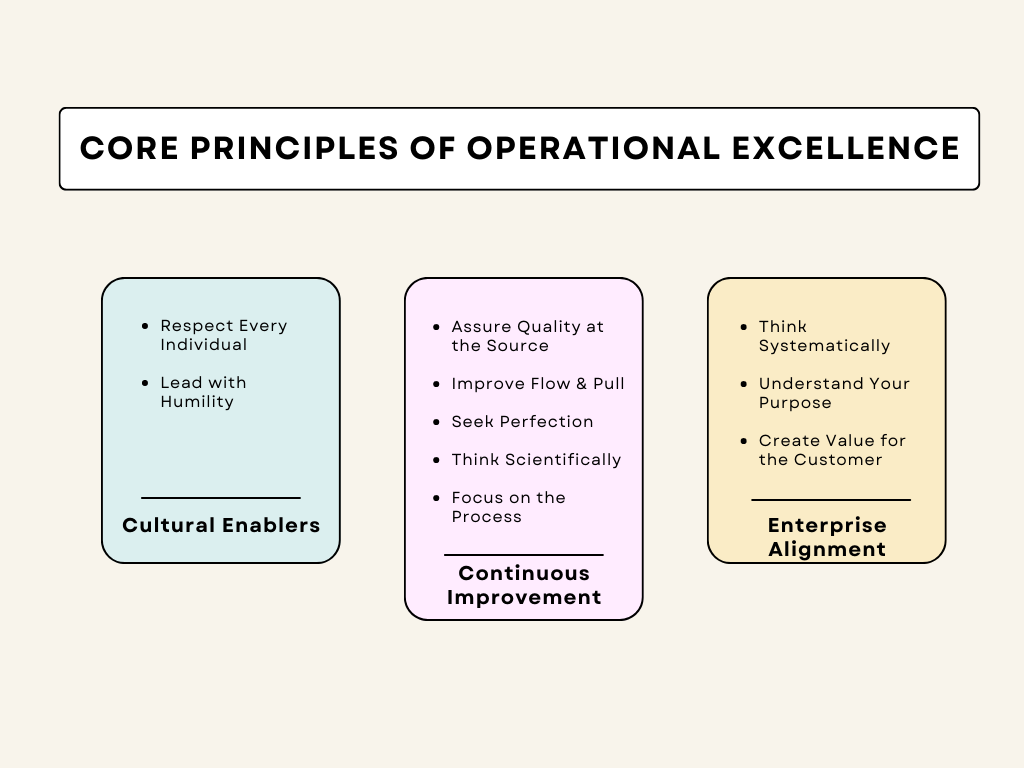

The Shingo Model is a framework that is designed to help organizations achieve operational excellence by creating a strong and sustainable environment for continuous improvement. You can think of this as a guide to building a better company by focusing on three key areas:

- Cultural enablers

- Continuous improvement

- Enterprise alignment

This model is also based on 10 core principles to help you navigate your way to excellence. These are:

1. Respect every individual

Respect should always be at the center of your operational excellence initiatives—especially if you want it to be a success. The Shingo model also emphasizes this by encouraging organizations to treat every one of their employees with dignity and respect. This is the foundation you’ll need to empower your staff.

But this respect goes beyond just recognizing their work. It also involves actively listening to their ideas, involving them in the decision-making process, and asking them for their input.

How to implement this principle:

- Ask for regular feedback from all your employees.

- Make your employees feel as though their ideas are valued by implementing them.

2. Practice humility

Humility (particularly in organizational leadership) is often overlooked. However, it plays an important role in creating an organizational culture of continuous improvement.

Practicing humility involves acknowledging that you don’t have all the answers and being open to learning from your staff. This should be true regardless of their position within your organization since this openness builds trust and encourages collaboration.

How to implement this principle:

- Create a mindset of growth across your organization where mistakes are seen as learning opportunities rather than stumbling blocks.

3. Strive toward perfection

Perfection is usually unattainable, but that shouldn’t stop you from striving for it.

By setting higher standards, you can push your organization and employees to constantly and consistently improve business processes. The key here is not to be discouraged by setbacks but to learn from them and improve over time.

How to implement this principle:

- Set ambitious (but achievable) goals for your process improvements and quality standards.

- Create a feedback loop where any progress toward perfection is regularly measured and celebrated.

- Establish clear performance metrics to encourage your employees to strive for excellence in their work.

4. Think scientifically

Without scientific thinking, there can be no innovation. This is why this principle encourages you to test your hypotheses, experiment, and use real data to guide your decision-making. Ideally, you should only use evidence-based practices rather than relying on historical trends within your business.

Remember: Part of thinking scientifically is reviewing your processes regularly. This will help you determine what is working and what isn’t.

How to implement this principle:

- Implement a structured approach to problem-solving, like the PDCA (Plan-Do-Check-Act) cycle.

- Use data analytics to guide your decisions.

- Encourage your employees to be innovative and think outside the box—failure is all part of the process.

5. Focus on the process

Effective processes are an important part of success. Often, the root cause of problems isn’t people; it’s flawed or inefficient processes.

So, by focusing on improving your processes, you can achieve more consistent and reliable results. Plus, when your processes are optimized, there’s less room for error. Your company will also benefit from better operational efficiency.

How to implement this principle:

- Conduct regular process audits to find inefficiencies and potential areas for improvement.

- Use process mapping tools to visualize your workflows and find opportunities for optimization.

6. Assure quality at the source

Rather than inspecting the quality of your product after the fact, operational excellence focuses on incorporating quality-checking into your business processes. This helps ensure that potential defects or errors are caught early and fixed at source.

This principle is especially important within the manufacturing industry. With a more proactive approach to quality, you can reduce waste, avoid costly delays, and improve consistency, which leads to higher customer satisfaction.

How to implement this principle:

- Implement preventative measures like standardized work procedures and quality control checkpoints.

- Use tools and workflow solutions that allow you to monitor quality in real time and enable problem-detection.

7. Improve flow and pull

Improving flow and pull is about minimizing waste by aligning your production with customer demand. In an ideal flow, your products and services should only be delivered when they’re needed and in the quantity you require. In turn, you can reduce overproduction and cut down on inventory costs.

To achieve great flow in your production process, you’ll need to plan how your processes will synchronize. Additionally, you’ll need real-time visibility into customer demand.

How to implement this principle:

- Implement Just-In-Time (JIT) production strategies to balance your production with actual demand.

- Use Kanban or similar tools to manage your inventory.

- Monitor your demand patterns continuously and manufacture your product accordingly.

8. Think systematically

Think of your organization as a machine with several moving parts. With this in mind, it’s clear that a change in one area can have a ripple effect throughout your entire business. This is why systematic thinking encourages you to think beyond isolated issues and consider how these changes will affect other parts of your organization.

When you take this kind of holistic approach, you can make more informed decisions that optimize your value stream.

How to implement this principle:

- Use system mapping techniques to visualize how different parts of your business are interconnected.

- Review and adjust your processes as a direct response to feedback from other parts of your business.

9. Understand your purpose

If you want to drive operational excellence, you have to have a clear purpose. When your employees also understand your company’s vision and direction—and how they contribute to this—you can improve employee productivity and motivation.

Having a ‘common purpose’ will unite your employees, ensure more consistent work, improve your decision-making, and place focus on your business’s long-term goals.

How to implement this principle:

- Regularly communicate your organization’s purpose with your employees.

- Make sure your purpose is reflected and modeled in day-to-day activities and your company culture.

- Create a link between every employee’s role and how it ties into your organization’s overall mission.

10. Create value for the customer

Ultimately, operational excellence is about delivering better value to your customers. This means every process and improvement should be looked at through the lens of a customer.

To do this, you’ll need to have a good understanding of what your customers need and expect from your organization. You should know their pain points and how you can solve them. In turn, your efforts will lead to better customer satisfaction and loyalty.

How to implement this principle:

- Gather as much customer feedback as possible and use it to improve your processes.

- Use customer-focused metrics to gauge satisfaction and guide your business strategies.

Operational Excellence Methodologies

Operational Excellence Methodologies

There are plenty of well-known companies that use different approaches to operational excellence, and there are plenty of valuable lessons you can learn from their example. However, the method you choose should complement your business needs and existing structure.

The most common methodologies include:

- Lean manufacturing: Lean manufacturing focuses on finding and eliminating waste in your processes. The goal here is to improve your efficiency and deliver more value to your customers by maximizing your resources while reducing unnecessary steps, costs, and delays.

- Kaizen (continuous improvement): Kaizen emphasizes making small but ongoing changes to your workflows. When you involve your employees, you can also use this method to create a culture of improvement where even the smallest changes can lead to big results over time.

- Six Sigma: This methodology uses data-driven strategies to minimize the amount of variability in your processes. In fact, it focuses on creating products of near-perfect quality by finding the root causes of errors and then implementing measurable solutions.

- Kanban: Kanban is a management system that helps your team track tasks, identify bottlenecks, and improve your workflows. It also gives you a way to prioritize work based on demand for smoother and more predictable processes.

- The 5-S system: The 5-S system stands for Sort, Set in order, Shine, Standardize, and Sustain. This helps to create a well-organized environment that focuses on cleanliness and order to improve efficiency.

How To Measure Operational Excellence

Measuring operational excellence typically involves tracking key metrics to assess how your organization is performing (and where you can potentially improve).

- Performance metrics: Metrics like customer satisfaction, product quality, and overall company productivity help show you how well your organization meets its goals.

- Employee engagement: Measuring employee engagement is essential for ensuring that you not only have a committed workforce but also encourage innovation.

- Process efficiency: This is measured through your waste reduction, cycle times, throughput, and more. It helps to give you an indication of how well your operations are optimized.

- Financial impact: Financial metrics like your cost savings or return on investment (ROI) can gauge how beneficial your improvements are in terms of your organization’s financial state.

FAQs

What are the four pillars of operational excellence?

The four pillars of operational excellence include the three main principles of the Shingo Method and one other crucial factor. They include:

- Cultural enablers

- Continuous improvement

- Enterprise alignment

- Results-driven focus

What tools can help my organization implement operational excellence?

There are several tools you can use to ease the transition into operational excellence. For example, you can use no-code software to simplify automation within your processes and free up resources to reallocate them to more high-value tasks.

You can also use tools like process mapping, lean manufacturing methodologies, and performance dashboards to track your key metrics and improve your processes according to feedback and data gathered from employees, customers, and stakeholders.

Final Thoughts

Achieving operational excellence may not mean perfection. However, it’s the closest path you can take to business success.

Now that you understand the principles, it’s time to make changes and take your organization to the next level using tools like HighGear and a new approach to business.

Operational Excellence Methodologies

Operational Excellence Methodologies